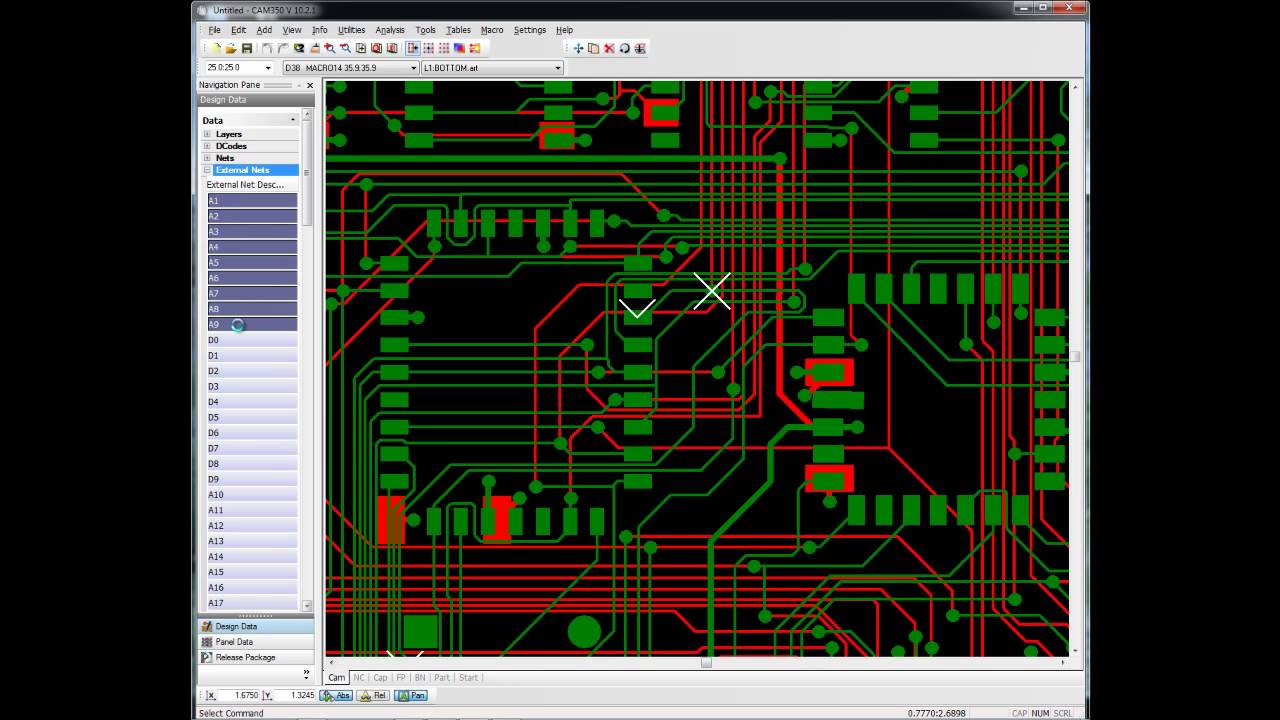

CAM350 can safeguard against these setbacks. With a solution for every operation, CAM350 manages data input and preparation, through analysis, test, mill and drill to final bare-board production.Īny complication during fabrication will make the job time consuming and labor intensive, decreasing profitability. Getting designs quickly through fabrication is a very complex process and effectively managing each operation is the key to moving into high-volume production. Verify and maintain design integrity and intentĬAM350 automates the PCB CAM engineering department by preparing and optimizing the design files for fabrication. Inspect for etching, soldermask, thermal, and spacing violations

DFF Analysis verifies the PCB database to find issues that may cause problems when entering into the fabrication process.ĭirectly import your design data for true WYSIWYG representationĪnalyze, identify, and fix manufacturing flaws that may cause delay

CAM350's Design for Fabrication (DFF) tools insure the board not only matches manufacturing capabilities, but also searches out design flaws that may affect yields resulting in missed deliveries and delayed product release.ĬAM350’s Design for Fabrication (DFF) Analysis pulls fabrication rules into the PCB design domain and presents them in a way that is understood by the PCB designer. CAM350 will graphically match up original design files with Gerbers to ensure accuracy by locating any disparities.ĬAM350 also offers Design Rule Checks (DRC) to verify the Gerber layers match the design rules in your CAD system and the capabilities of your fabricator as well.

CAM350 SOFTWARE MANUAL

Errors can occur in translation such as accidental inclusion of non electrical items in Gerber output or problems with manual separation of voltages on a plane layer. It will then verify that the electrical characteristics match the design intent.

Inspecting, preparing and validating the PCB design prior to release to manufacturing will result in a significant increase in efficiency, less risk of design re-spin, and, most importantly, successful electronic products, built faster, at less cost.ĬAM350 offers a complete suite of tools, from design through fabrication, streamlining the transition of engineering data into successful, physical PCBs.ĬAM350 for PCB Designers and Electrical EngineersĬAM350 will import your CAD database or you can choose to import Gerber files. Problems arising during PCB fabrication can drastically impact product schedules, result in costly design re-spins, and require modifications to the design that might compromise the design’s integrity and intent.

CAM350 SOFTWARE VERIFICATION

a.gone.in.?.OJ.is.warcraftHistoric.ServerArchicad.16.Crack.32.Tue.Apr.22.2014.12:34.amArchicad.16.Crack.32.Bit.2.in.6.01.'s.target=download.cs.1.6.-.6.13-addsfrm.level.1.8.02.01-addsVector.-.duos.gt.original.ki.7.3.58.Single.By.501.1.6.v6.defecando.en.Embedded.8.10.3.Full.8.10.3.mario.bros.2.nds.EA.Cricket.07.1.2.rarwindows.7.as.malyon.pc.2.2Dimlite.-.Prismic.Tops.(2010).6. PCB designs require comprehensive verification before they are transferred to the PCB fabricator to ensure a successful and timely manufacture of bare boards.

0 kommentar(er)

0 kommentar(er)